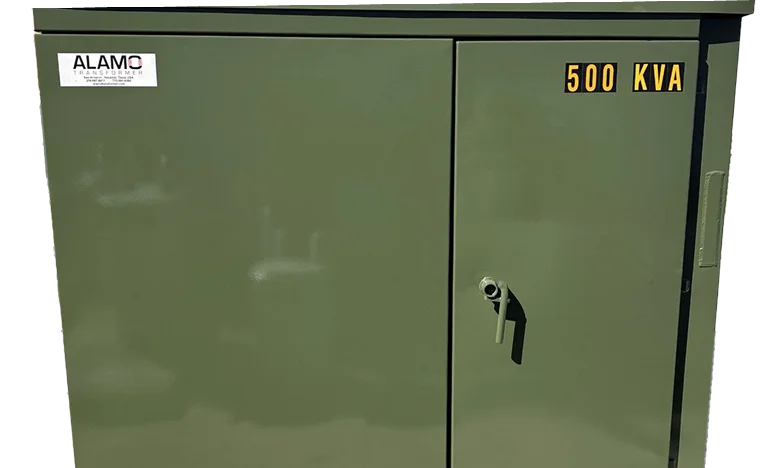

Available in multiple configurations, these transformers are built for high-voltage applications and can be customized to meet your specific needs.

The Technical Specification section below serves as a resource providing a general overview of the key components and features for this type of product.

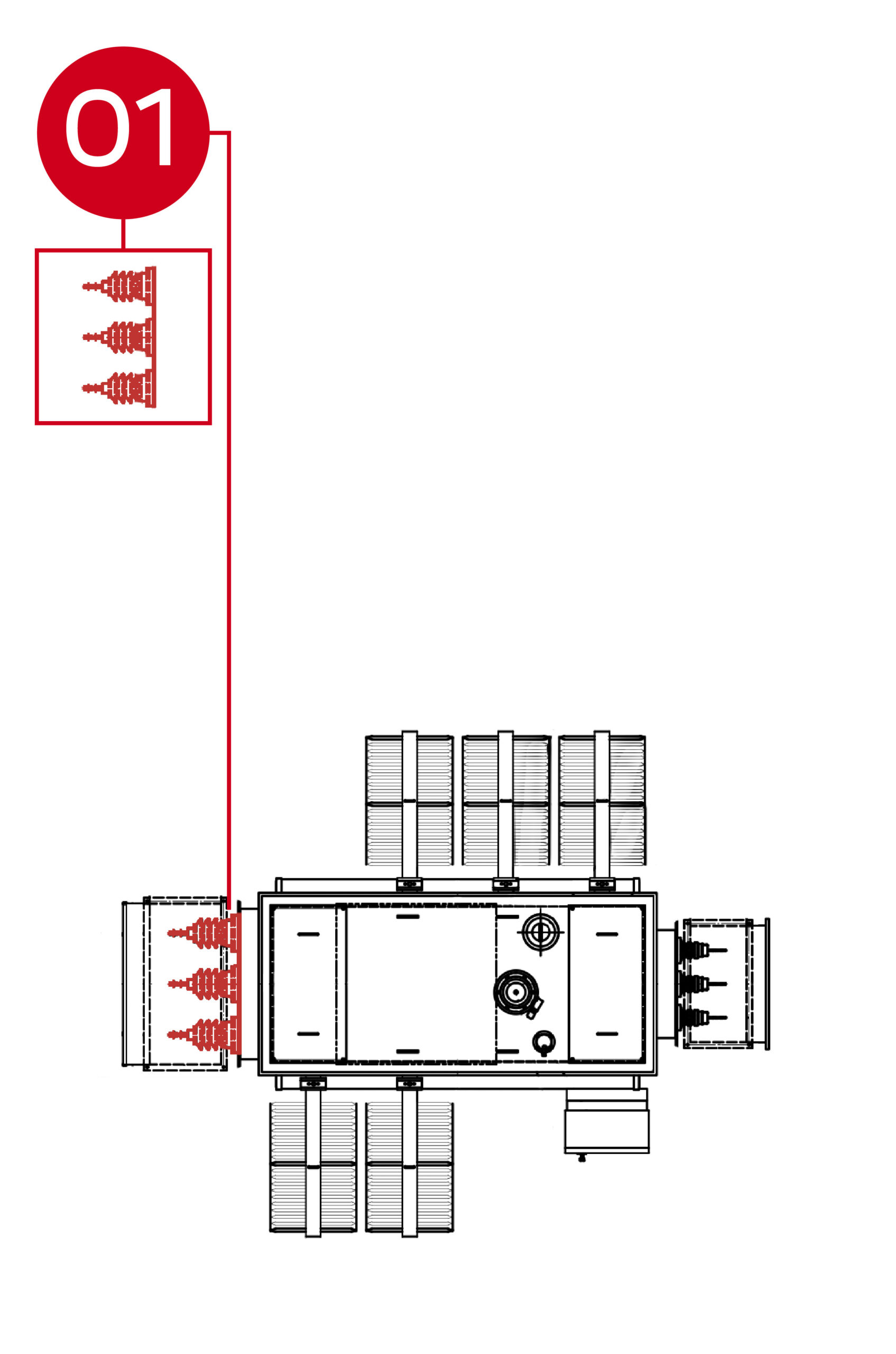

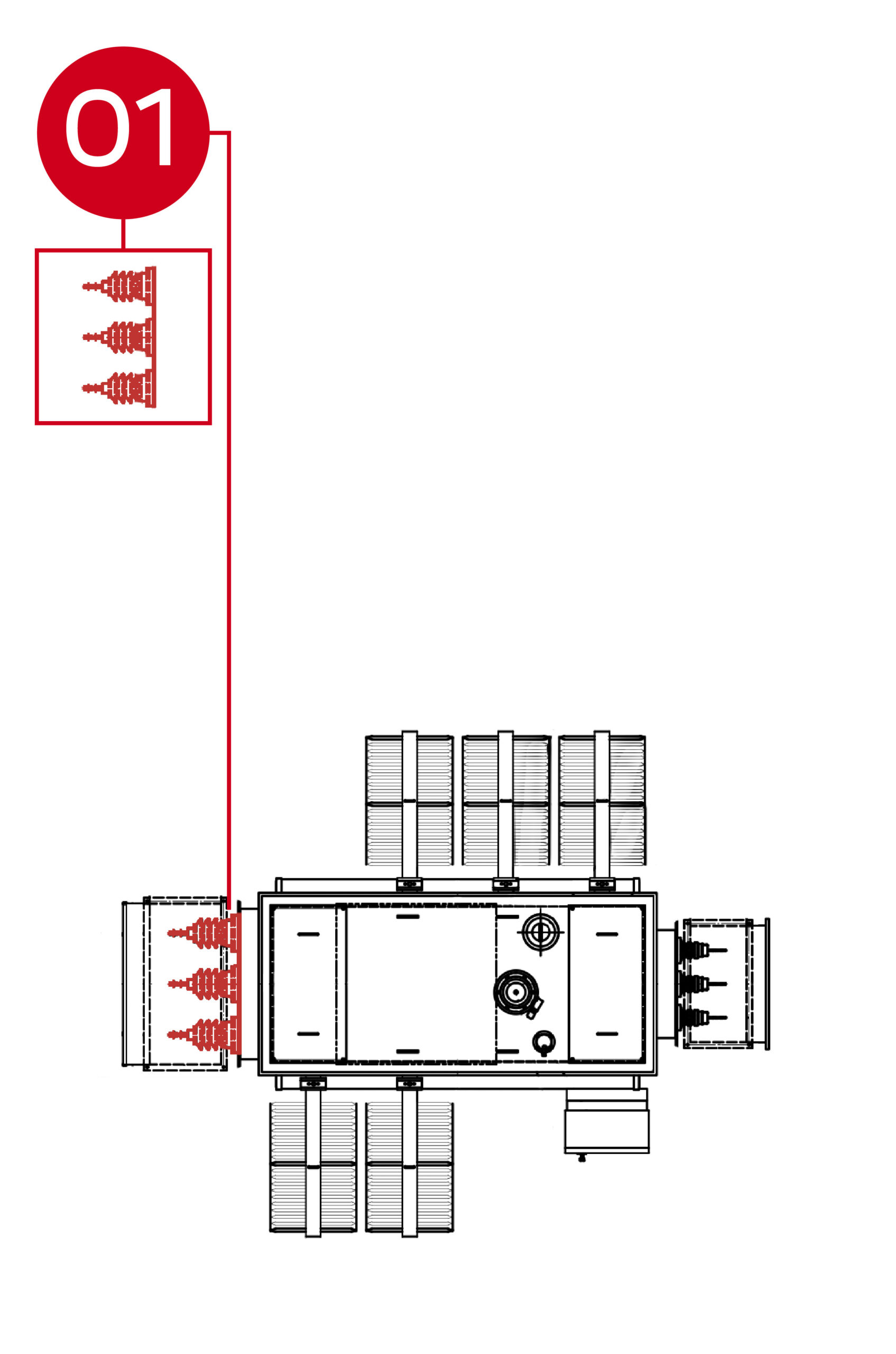

High Voltage Bushings – Insulated connection point for incoming high-voltage supply cables.

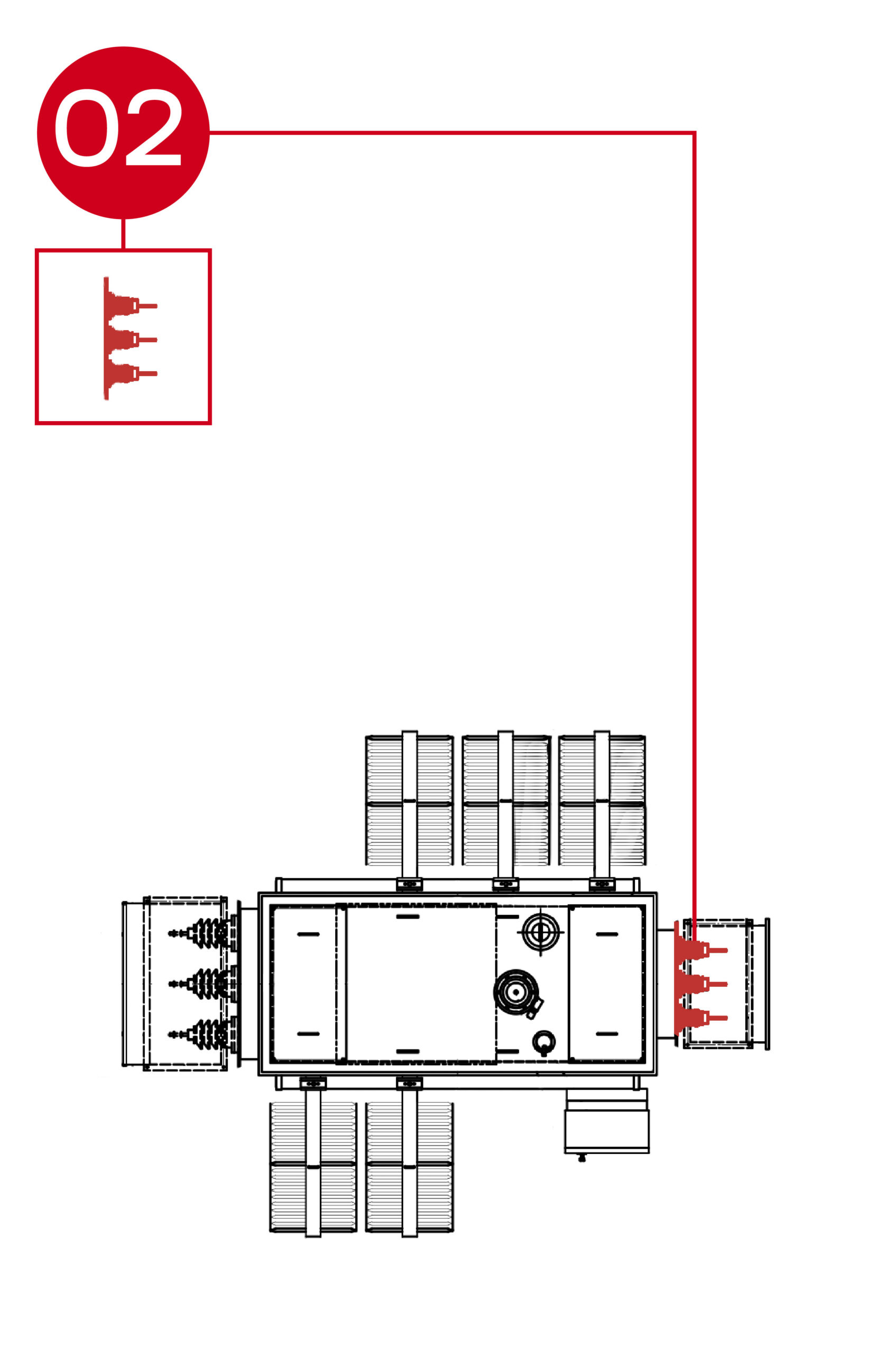

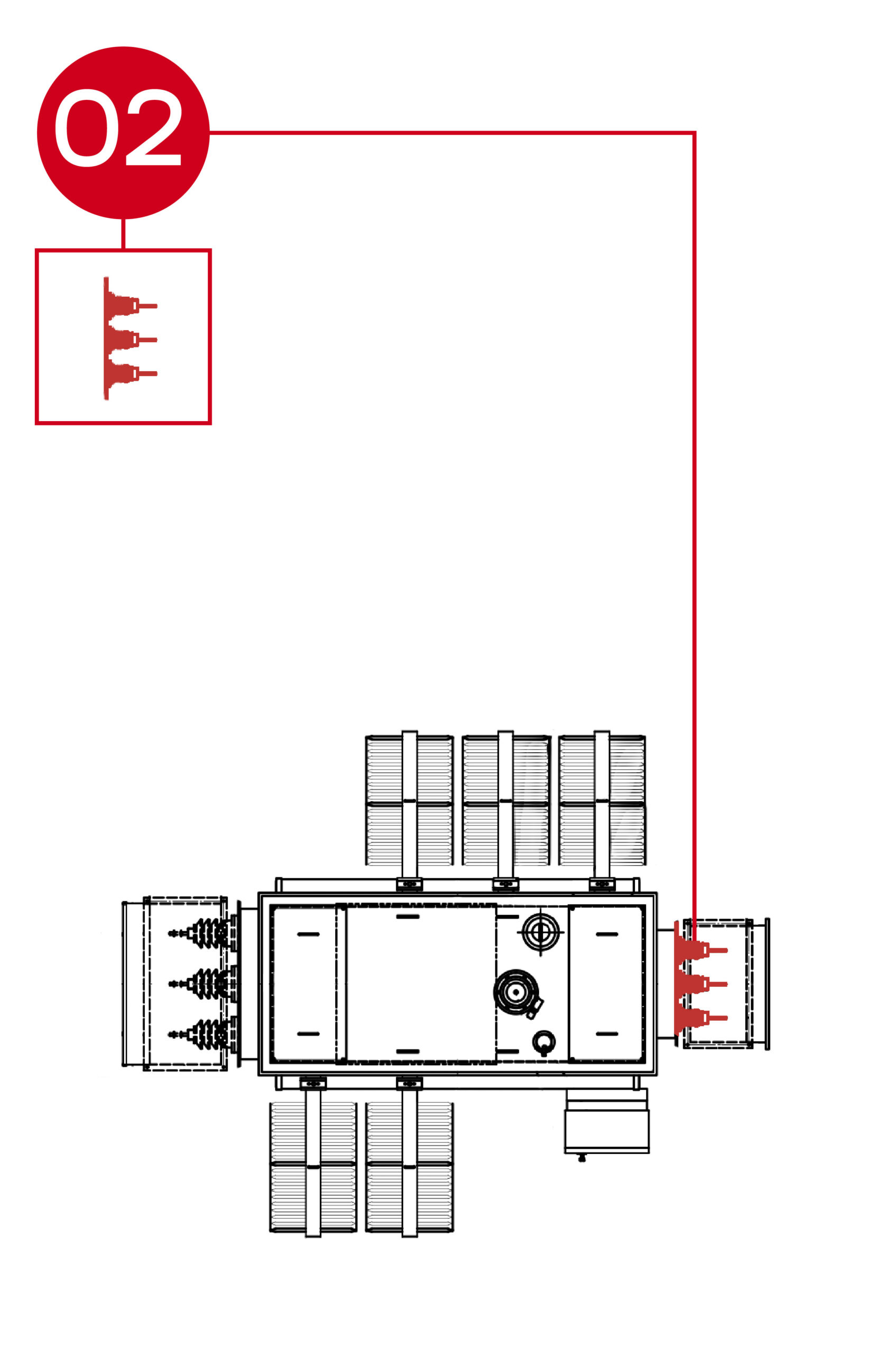

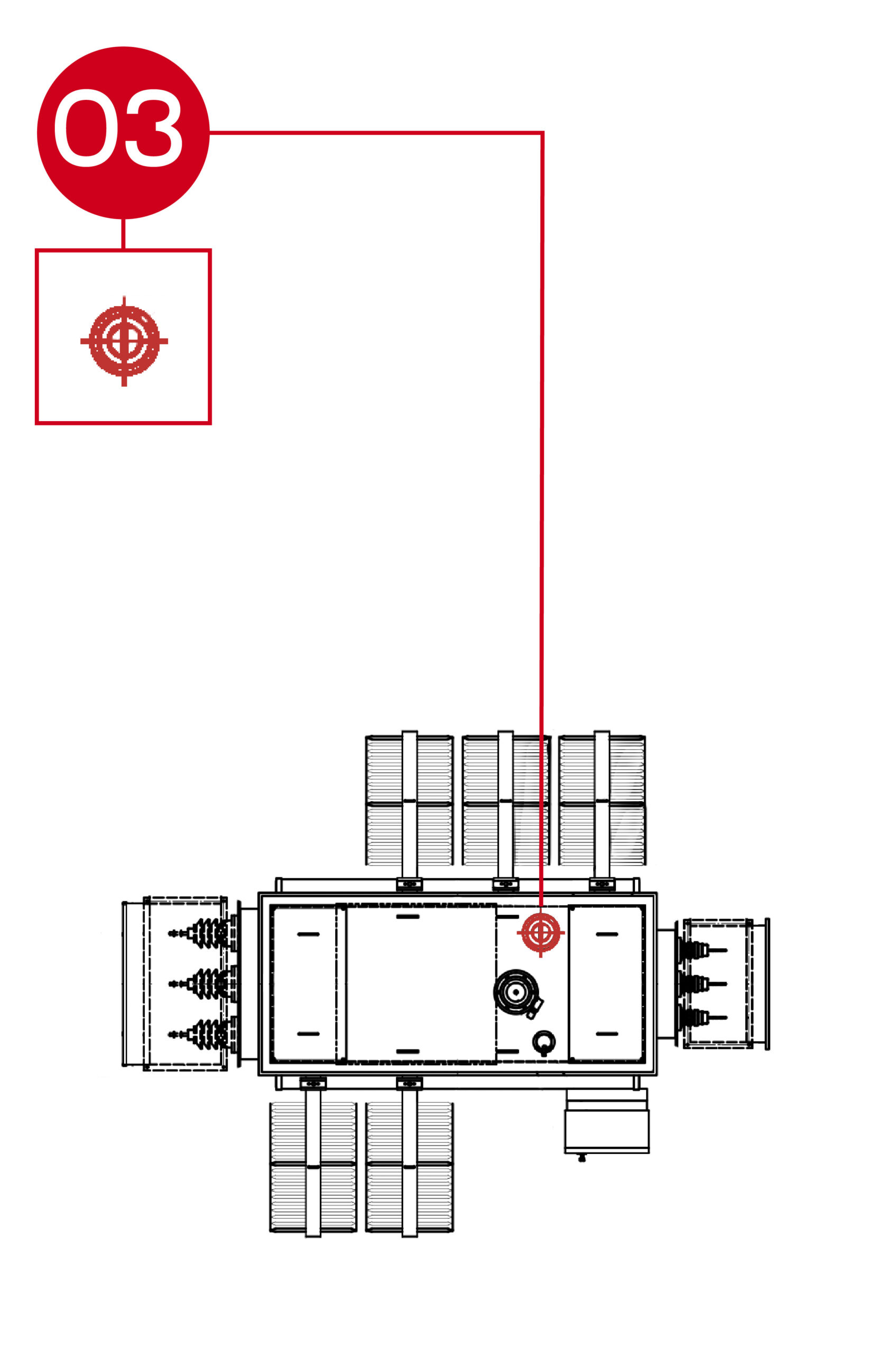

Low Voltage Bushings – Low Voltage output points

Low Voltage Neutral Bushing – Provides a method for grounding the low voltage winding either by direct ground or through a resistor for ground fault control.

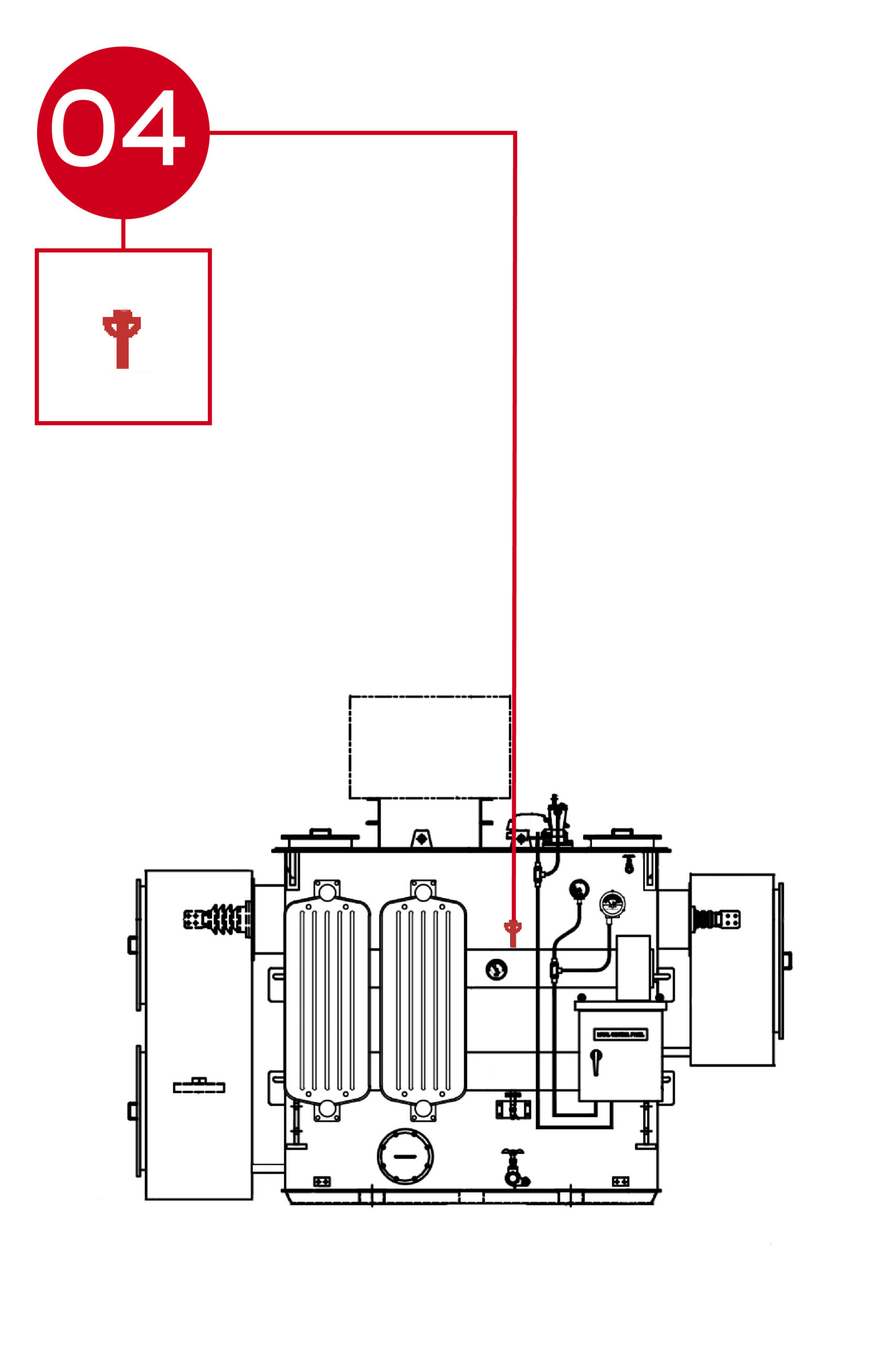

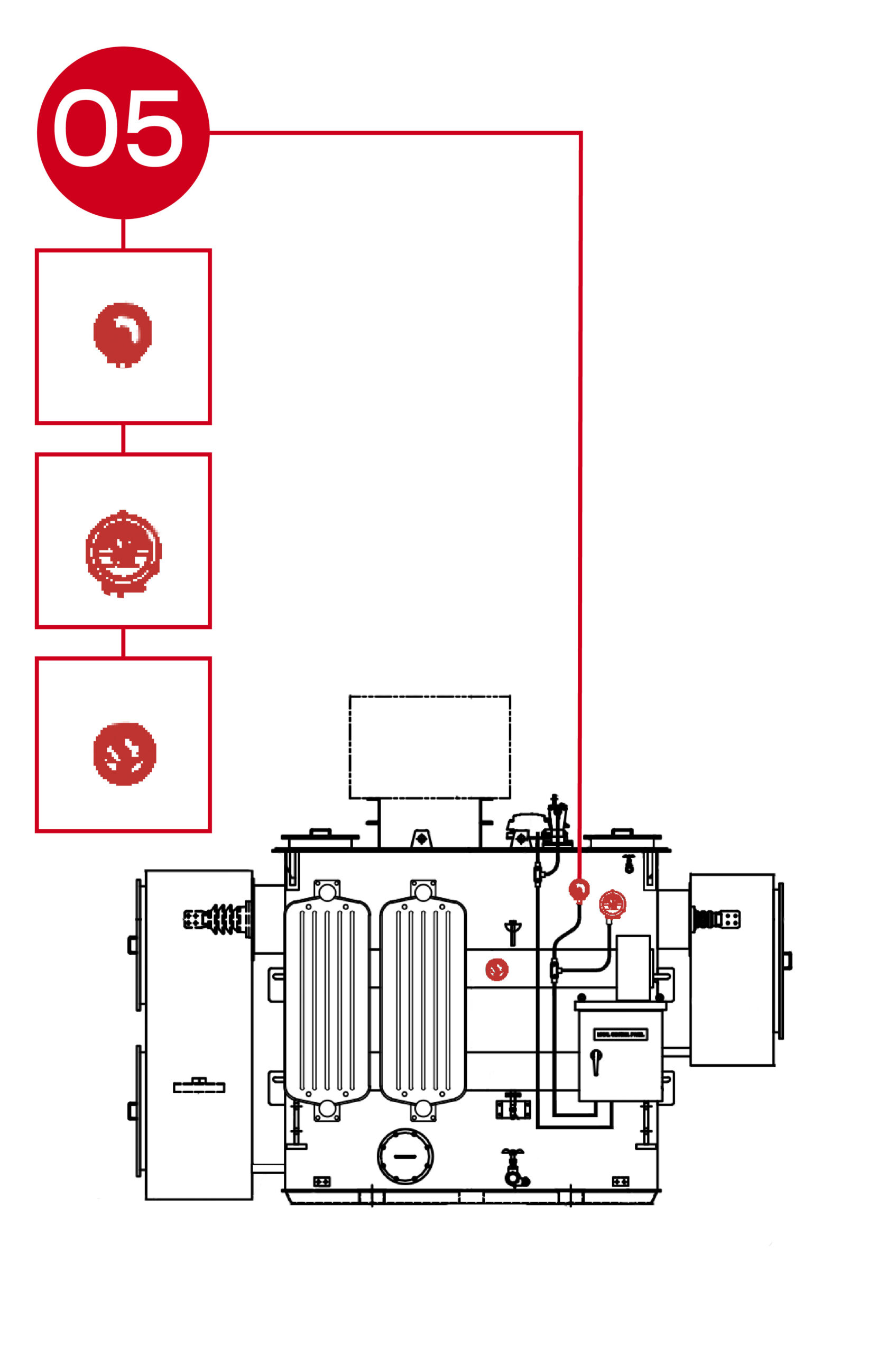

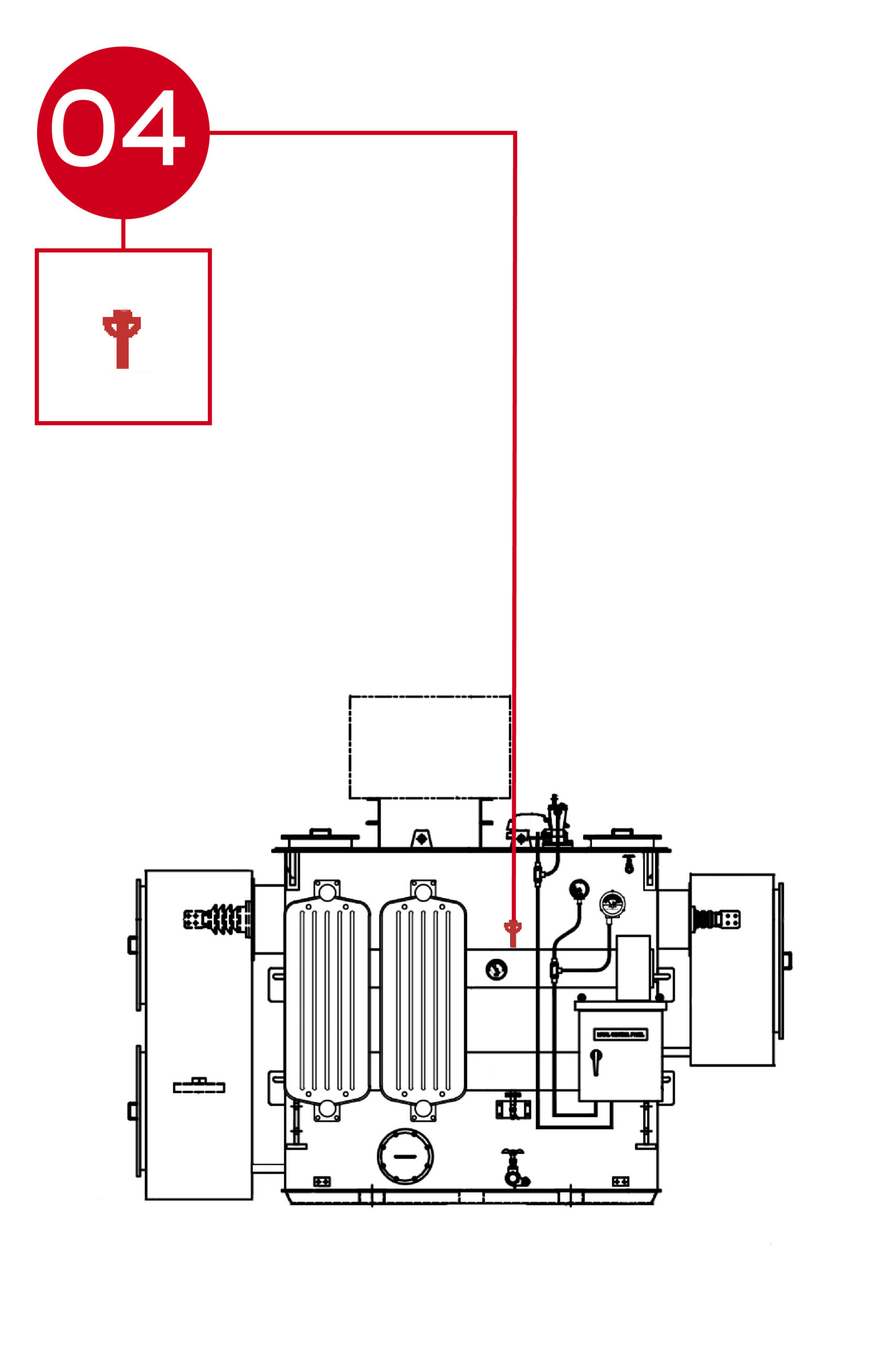

Tap Changer – Used to match incoming voltage and adjust outgoing Low Voltage

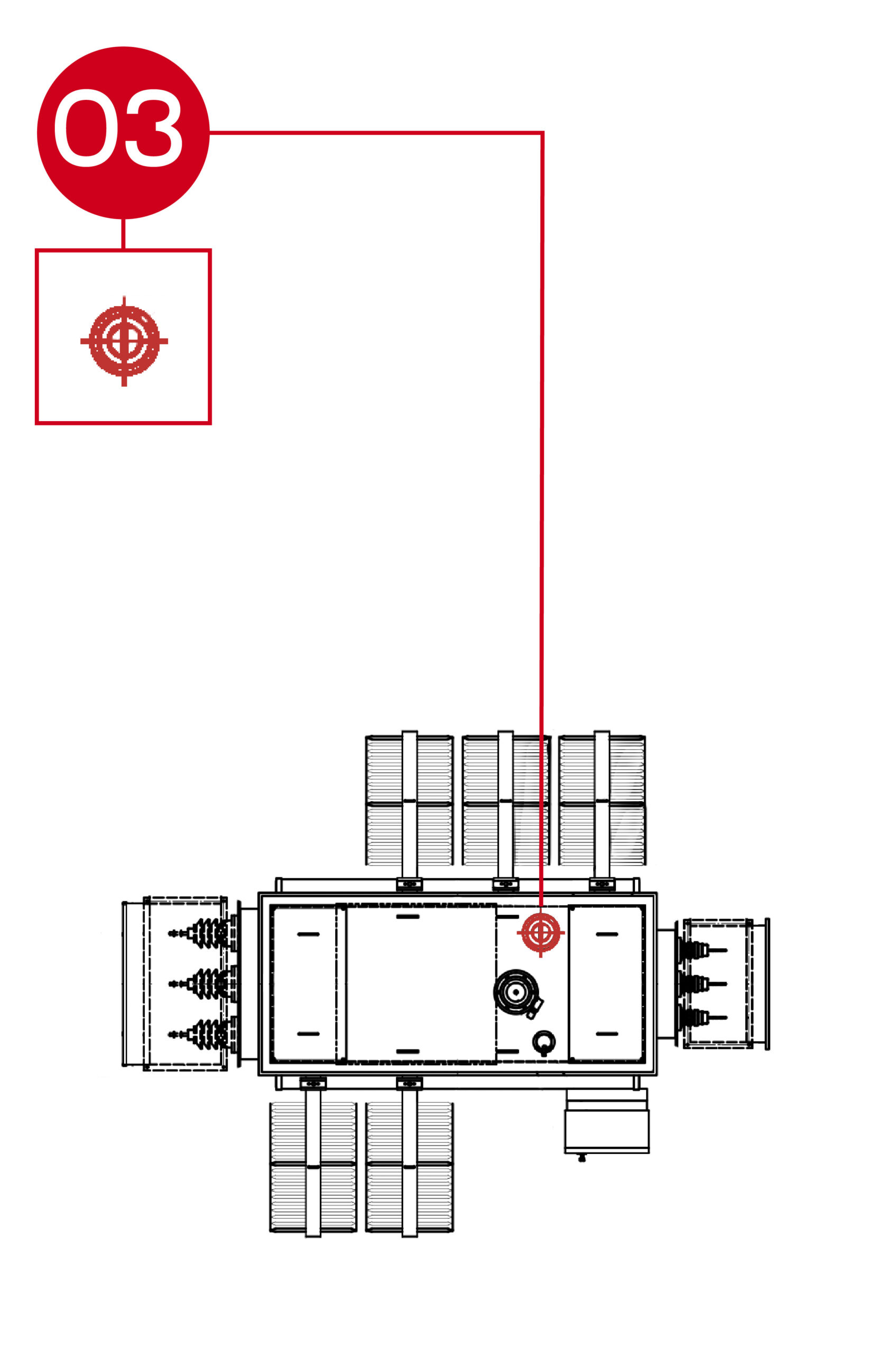

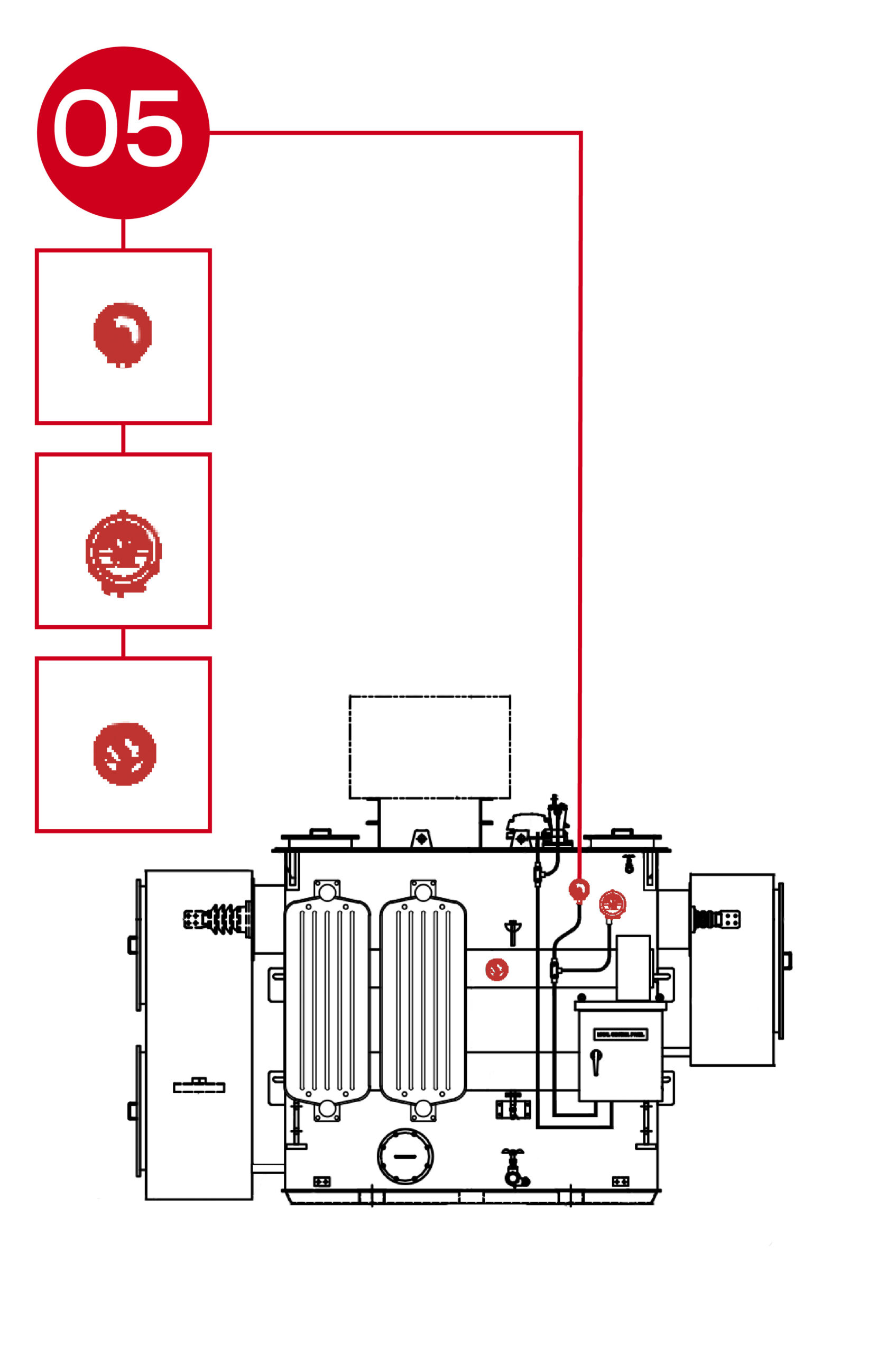

Standard Gauge Package – A combined monitoring assembly integrates vital indicators for transformer health and safety.

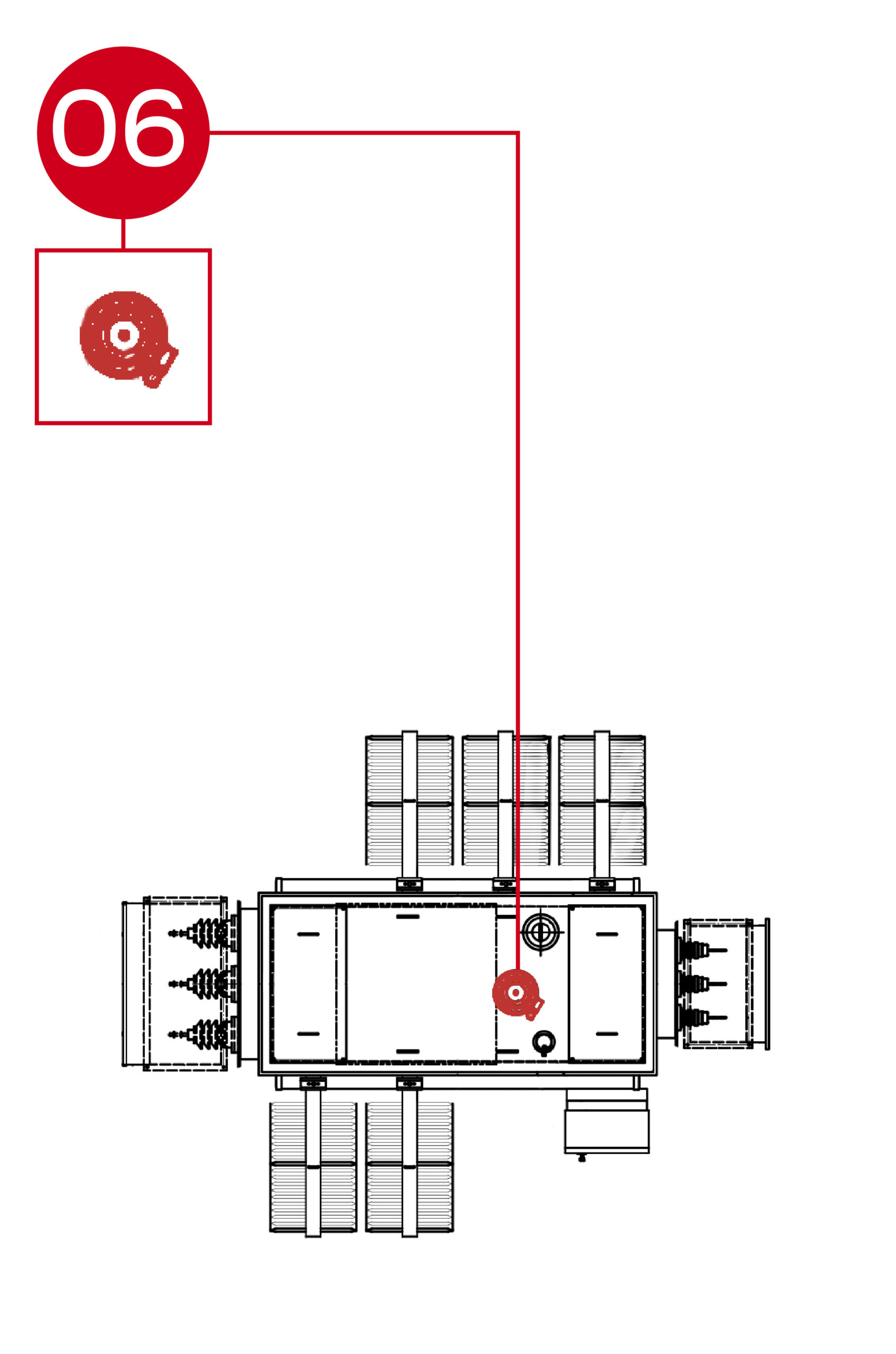

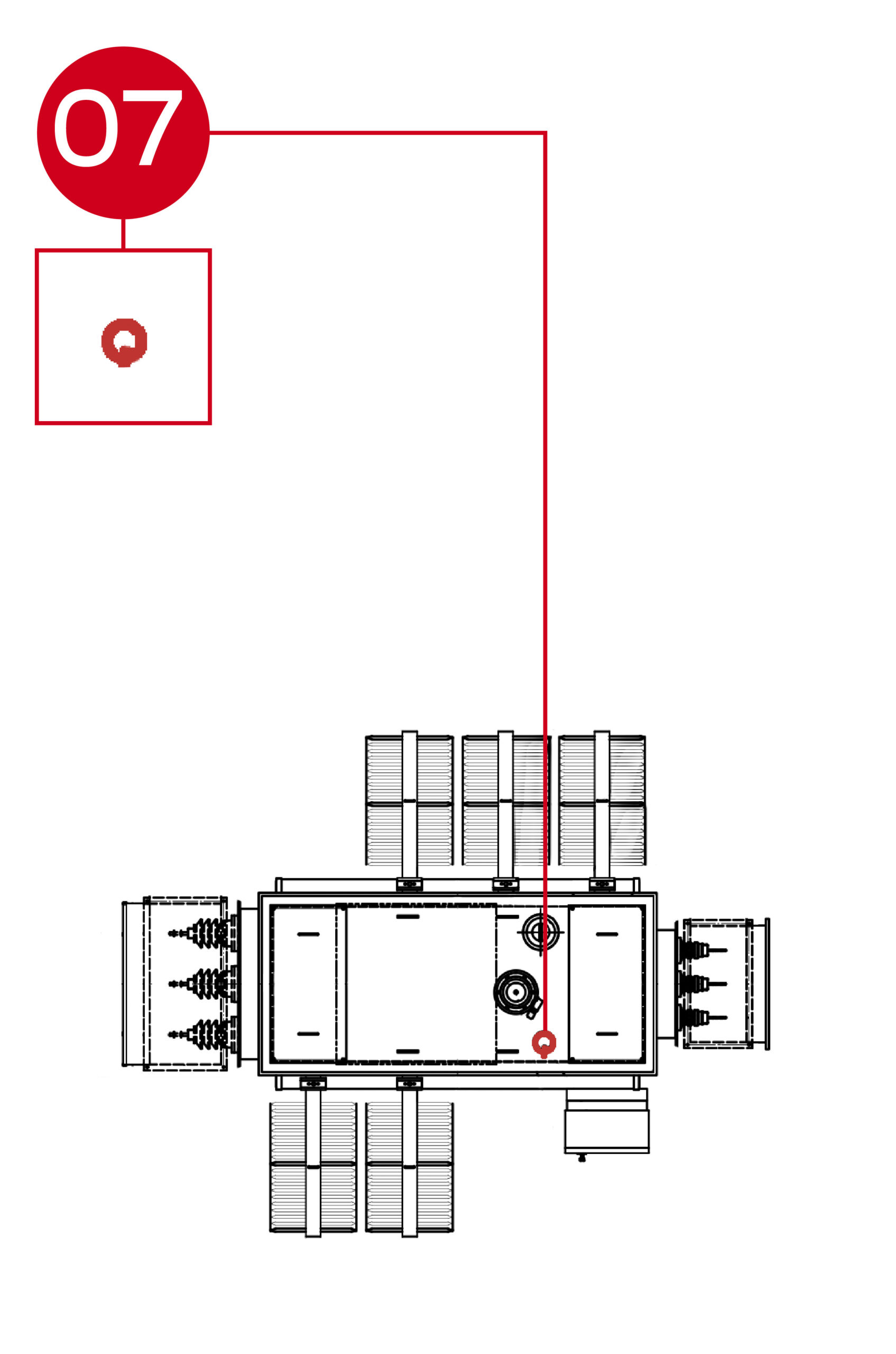

Pressure Relief Device – Used to automatically vent excess internal pressure caused by a transformer event or fault, to prevent catastrophic damage to the transformer tank.

Rapid Pressure Rise Relay – The RPRR is designed to operate in conjunction with the Pressure Relief Device, except that it very quickly

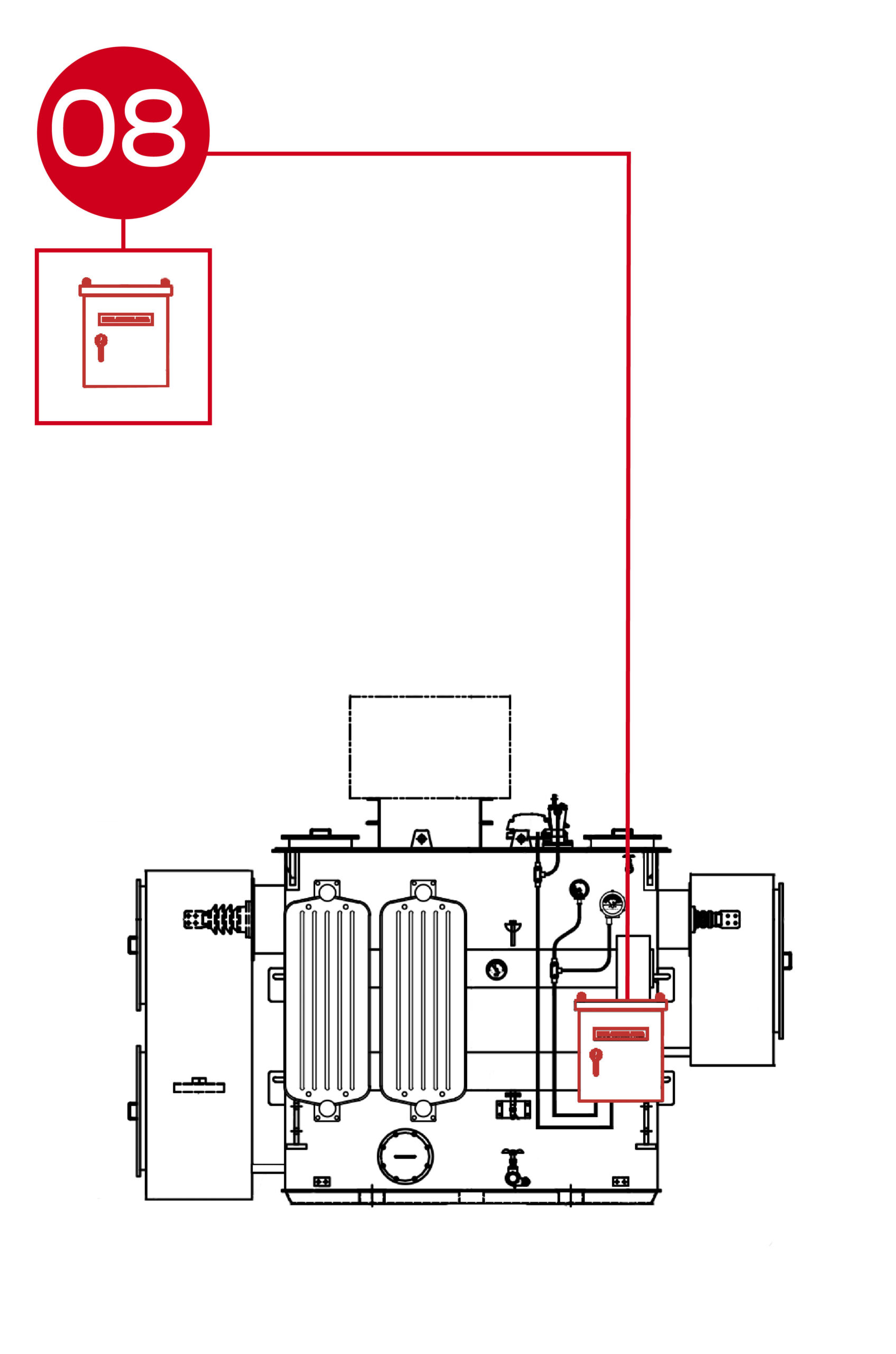

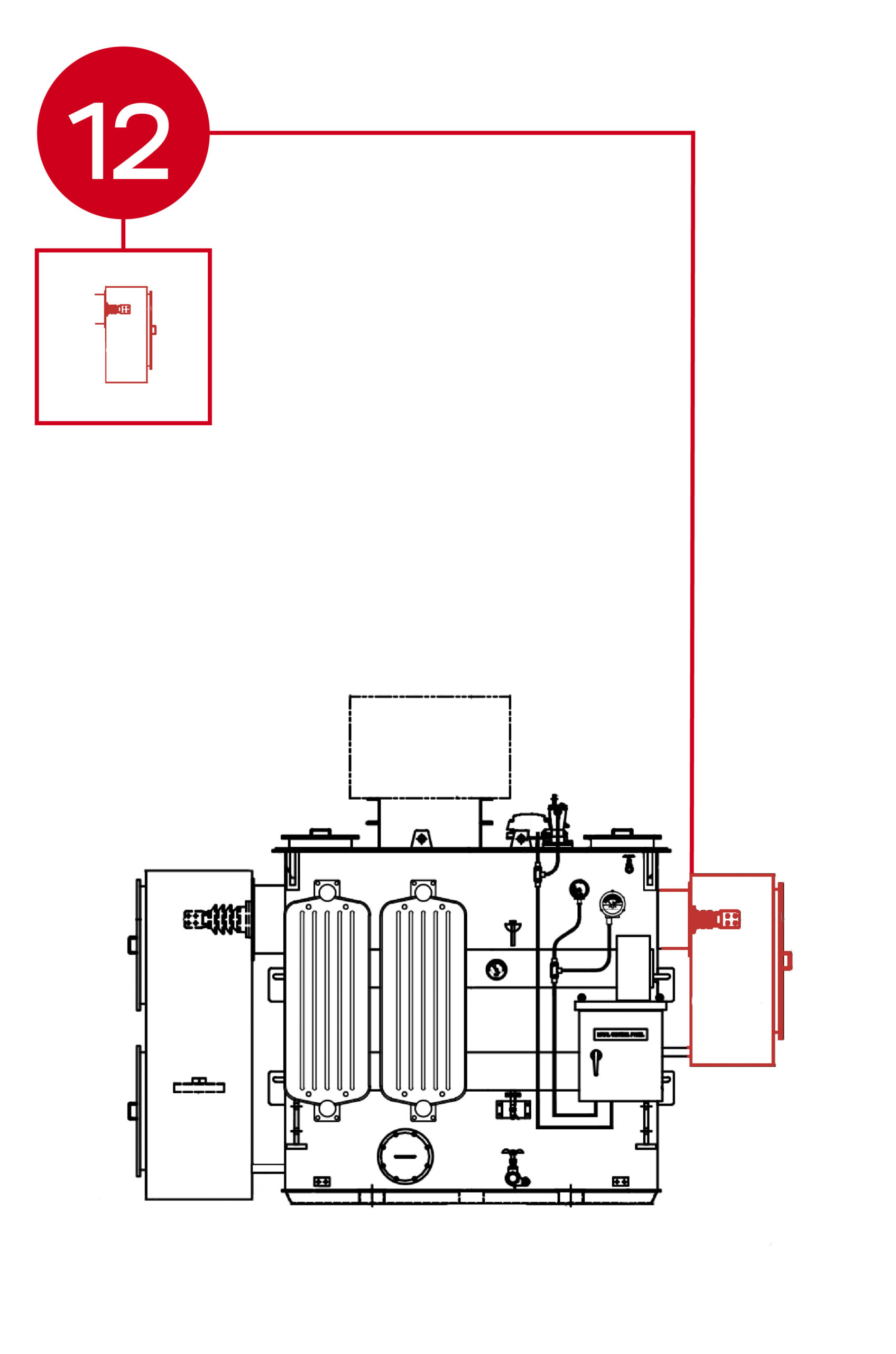

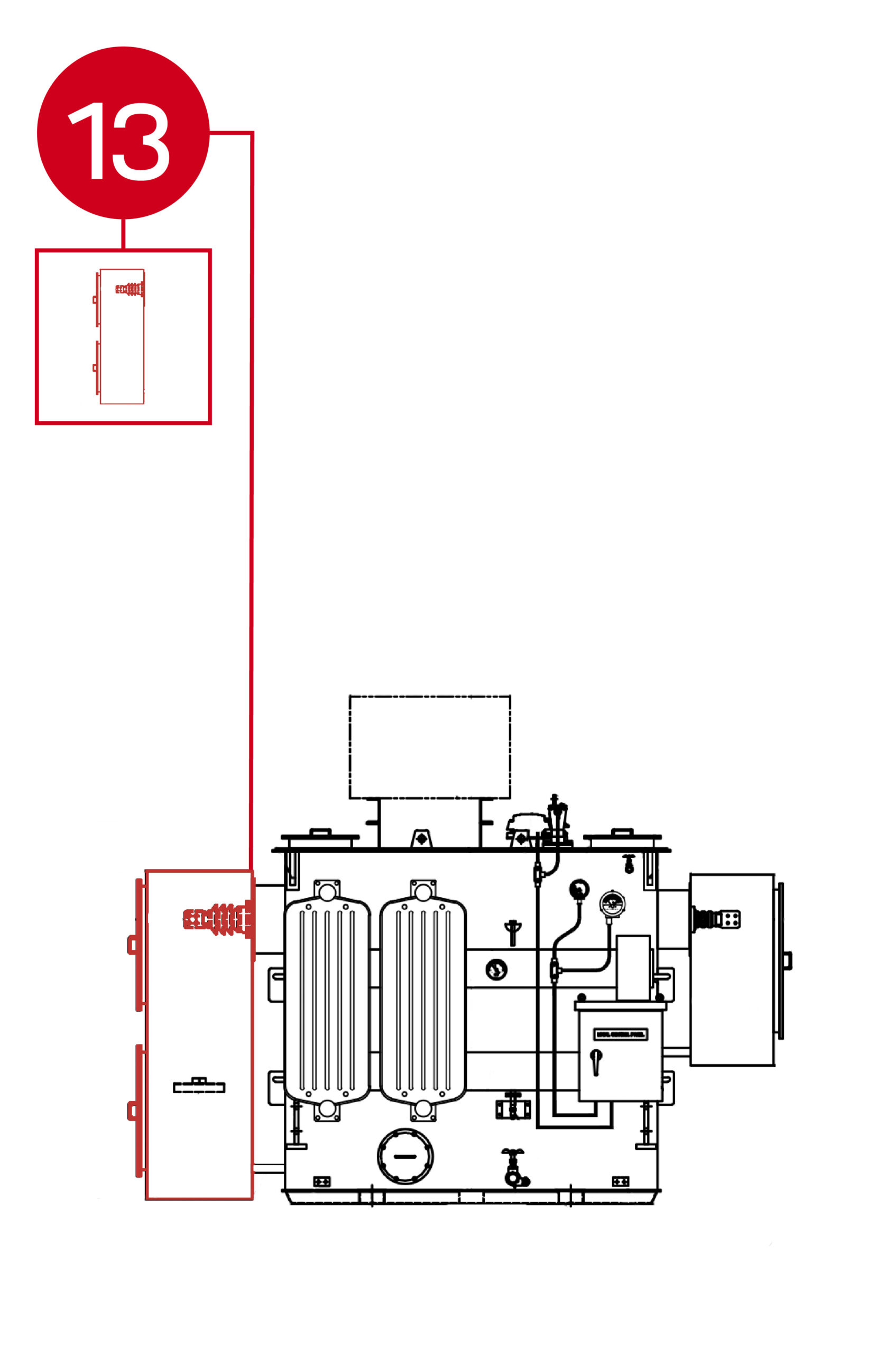

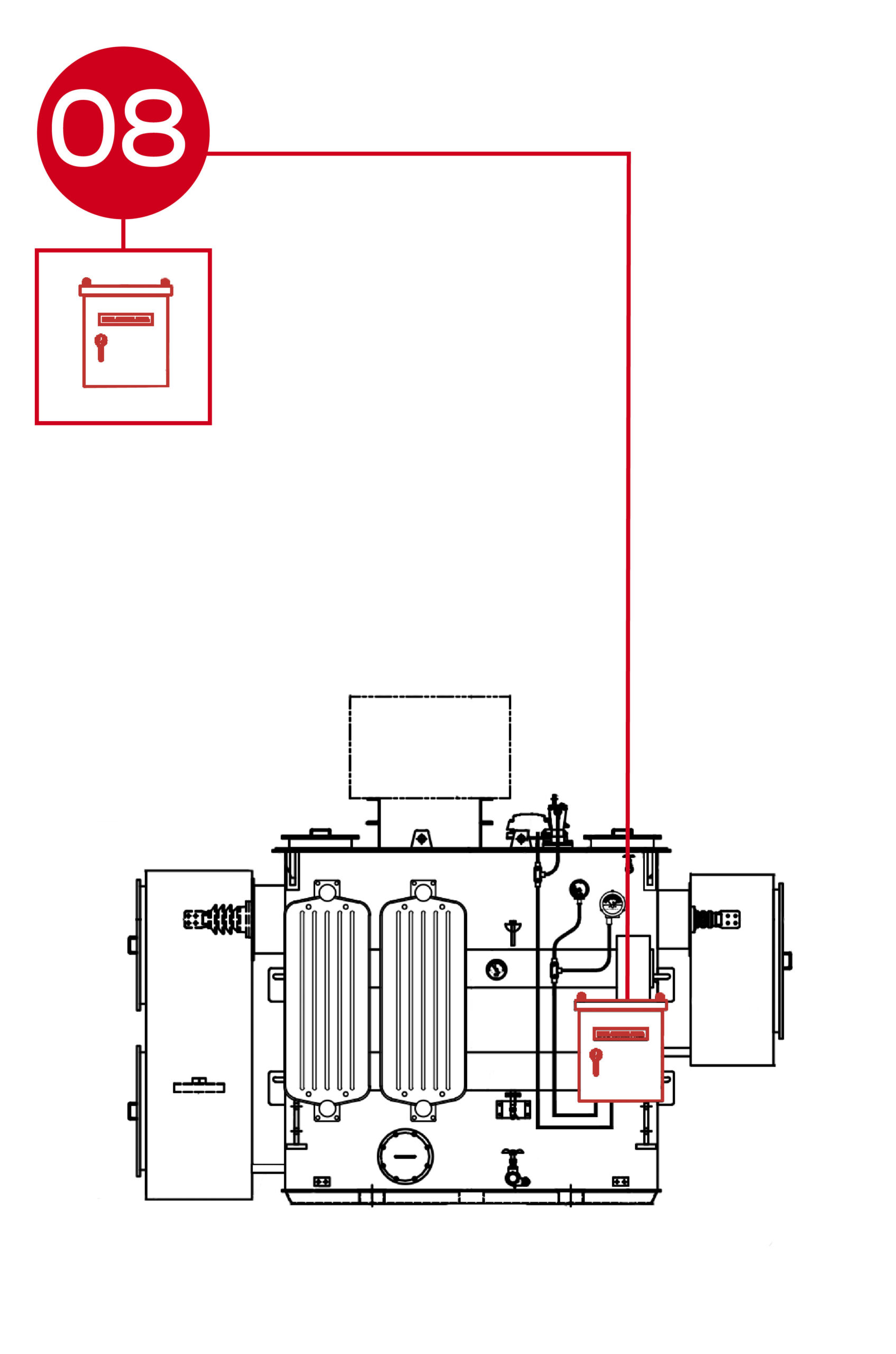

Control Panel Cabinet – The local control panel houses controls, indicators, and relays for transformer operation and protection.

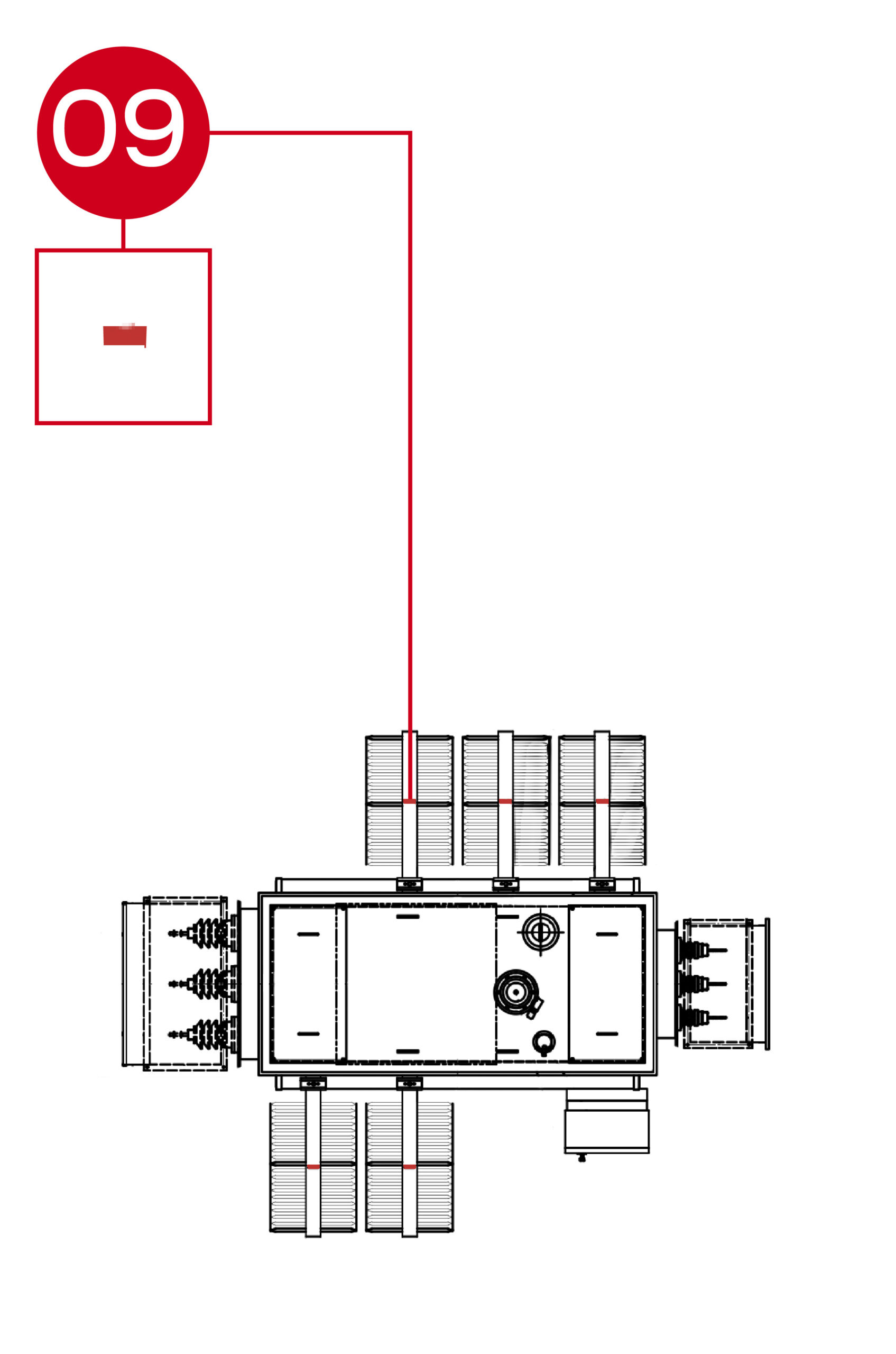

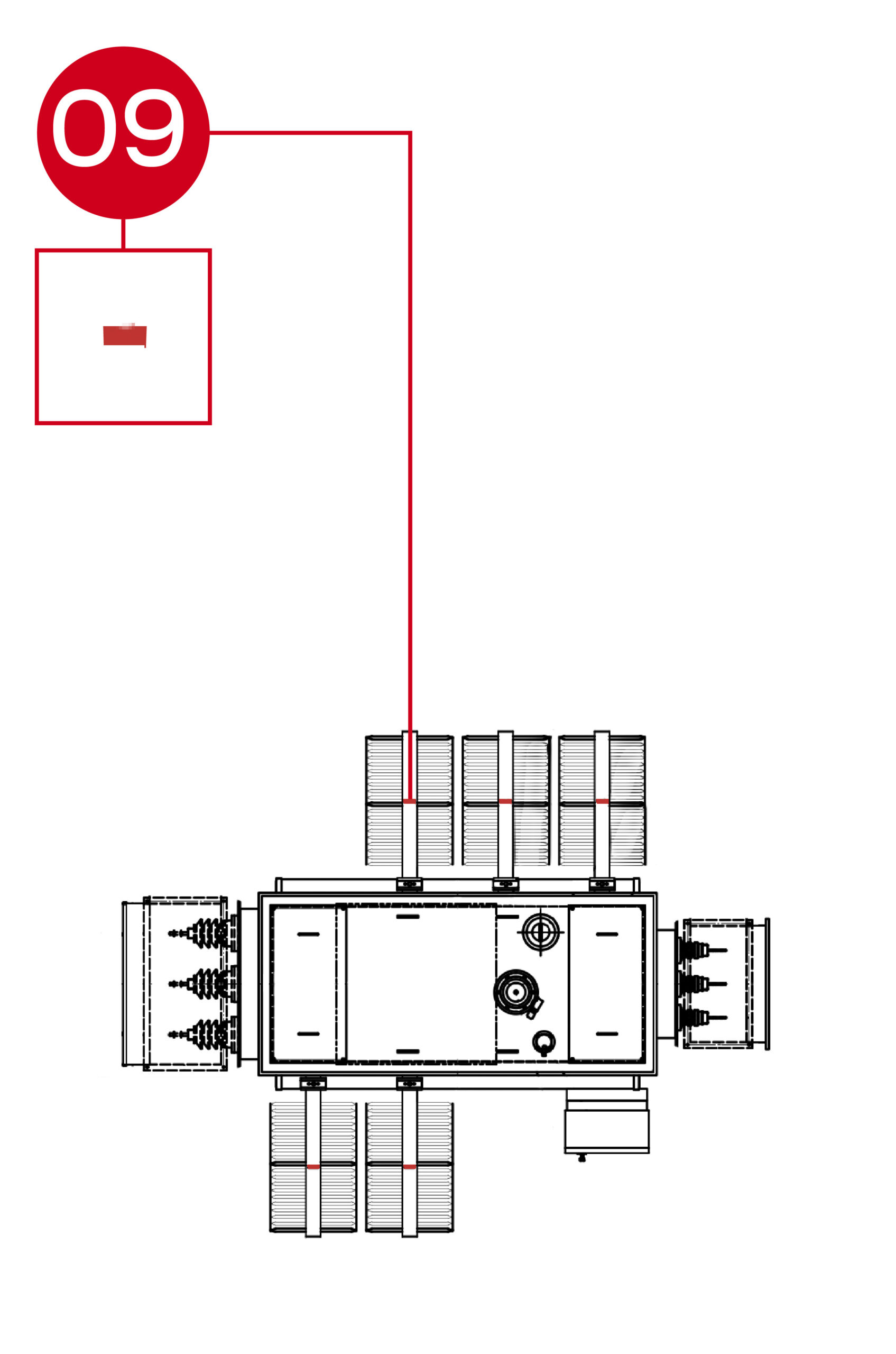

Radiators dissipate heat from the transformer’s insulating oil to maintain safe operating temperatures.

Location: Attached externally along the transformer sides.

Layout: Multiple finned panels or tubular sections bolted to the tank.

Function: Facilitates oil circulation and heat exchange, ensuring efficient cooling.

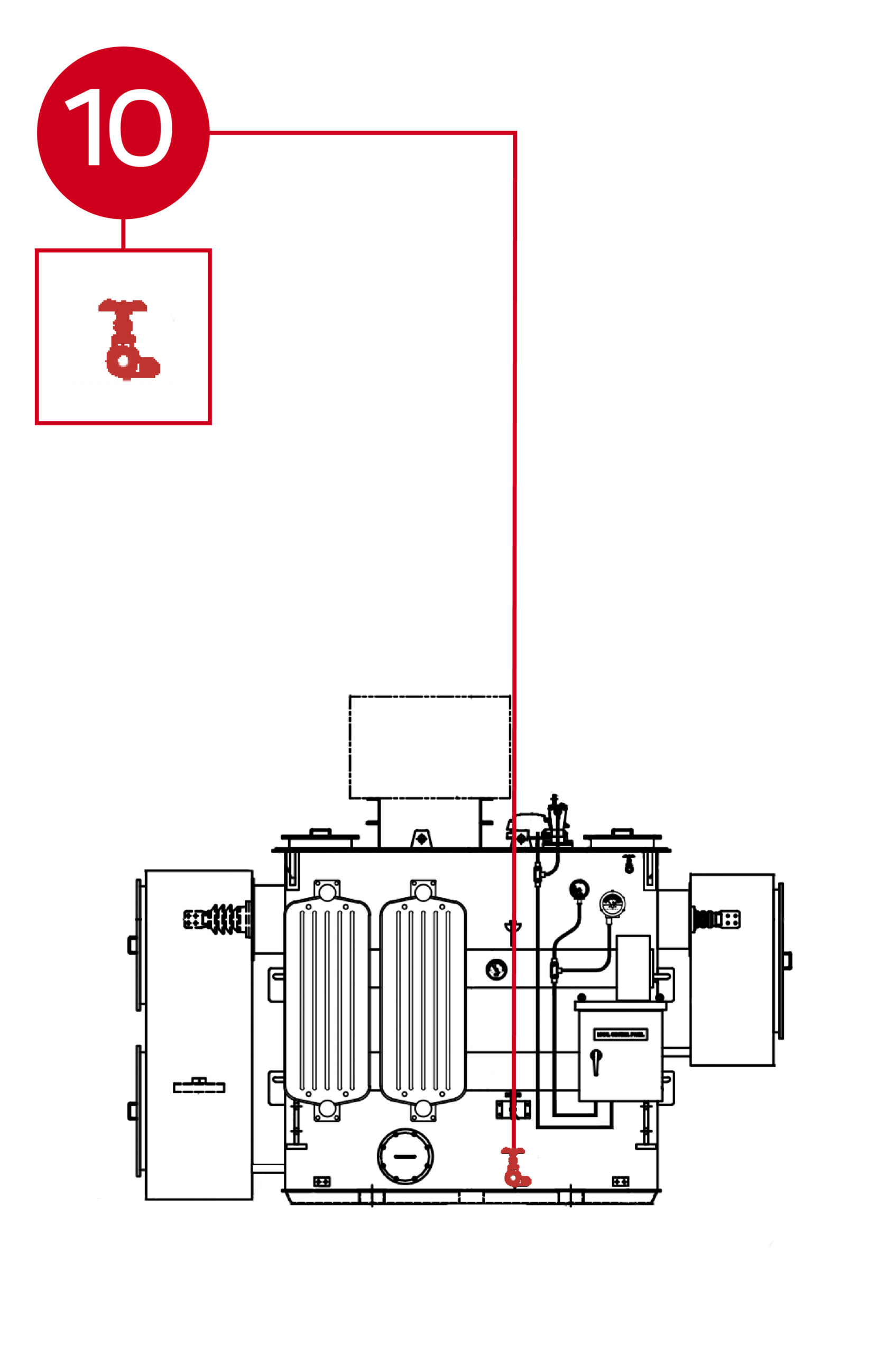

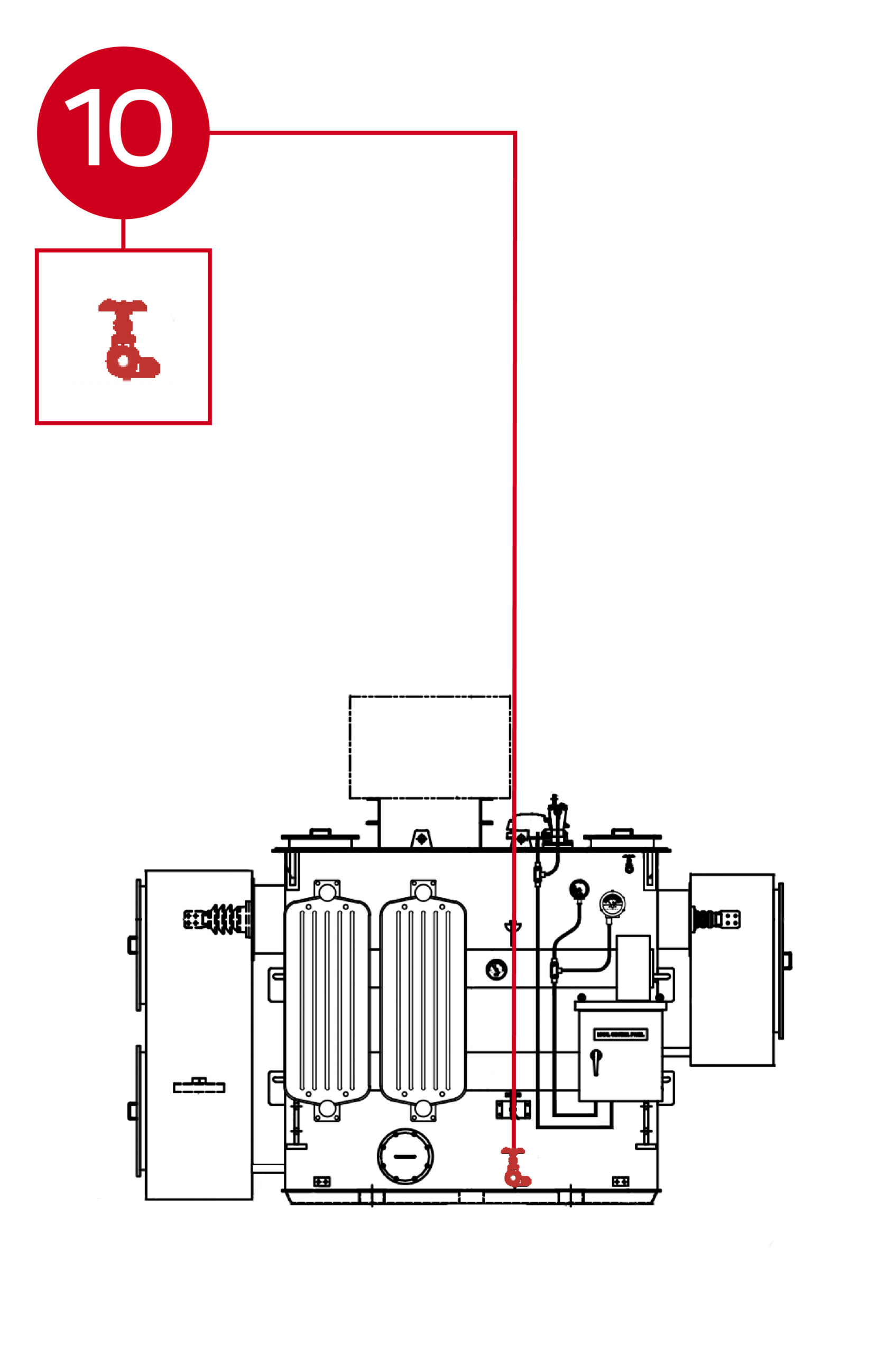

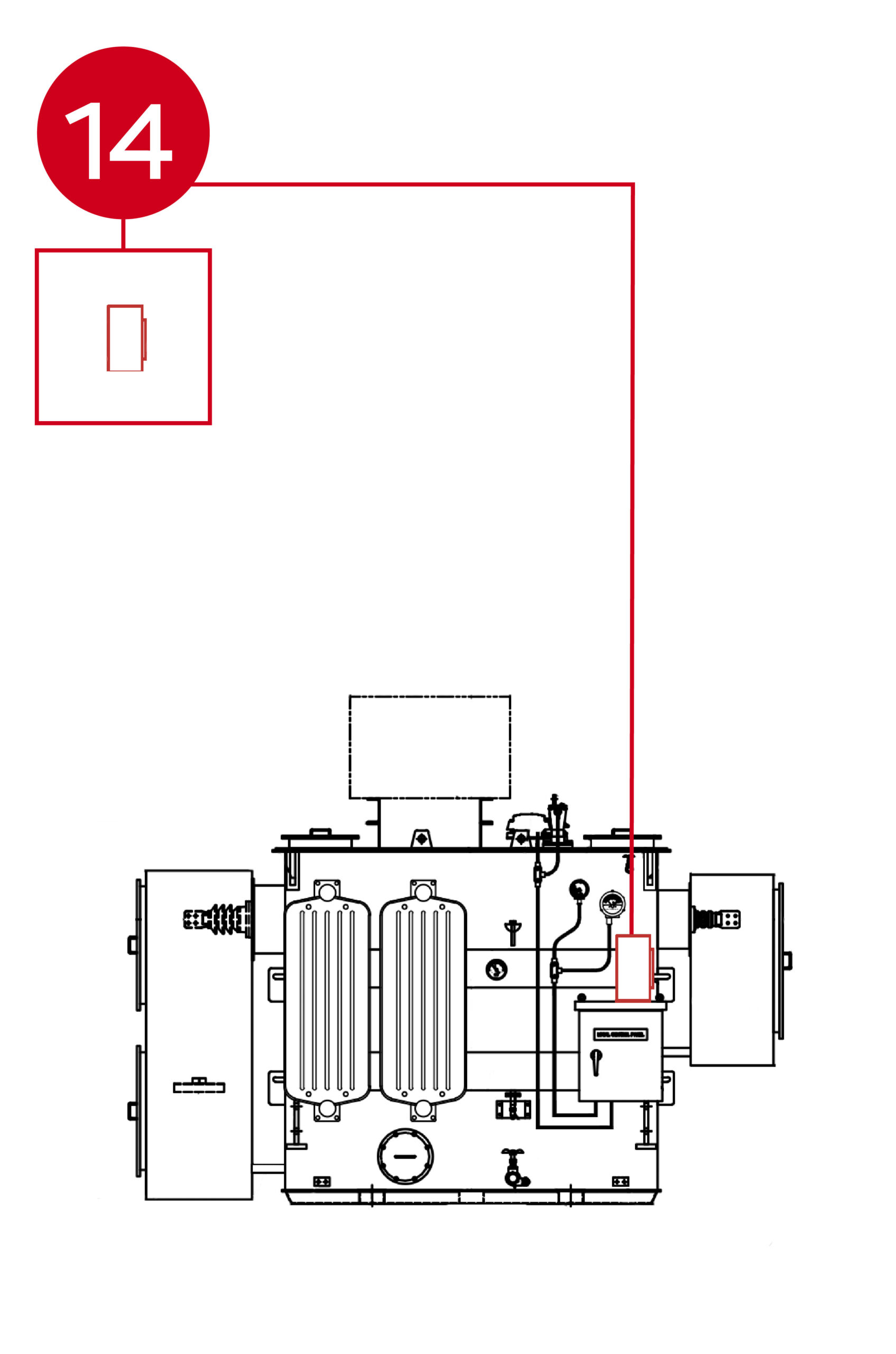

Drain Valve – Designed for safe oil management during maintenance or fluid sampling.

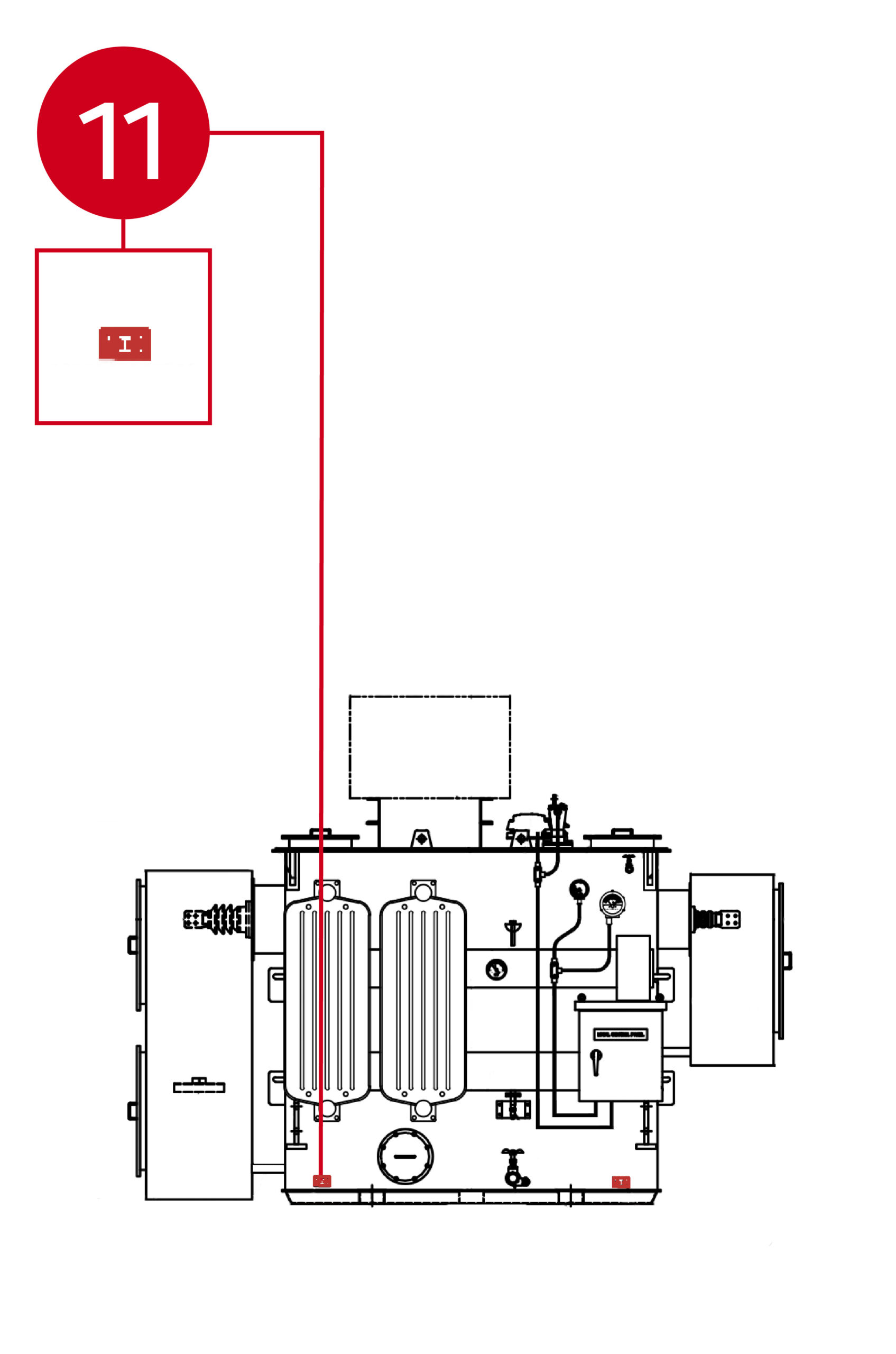

Grounding Provisions – Provides various acceptable safety grounding points

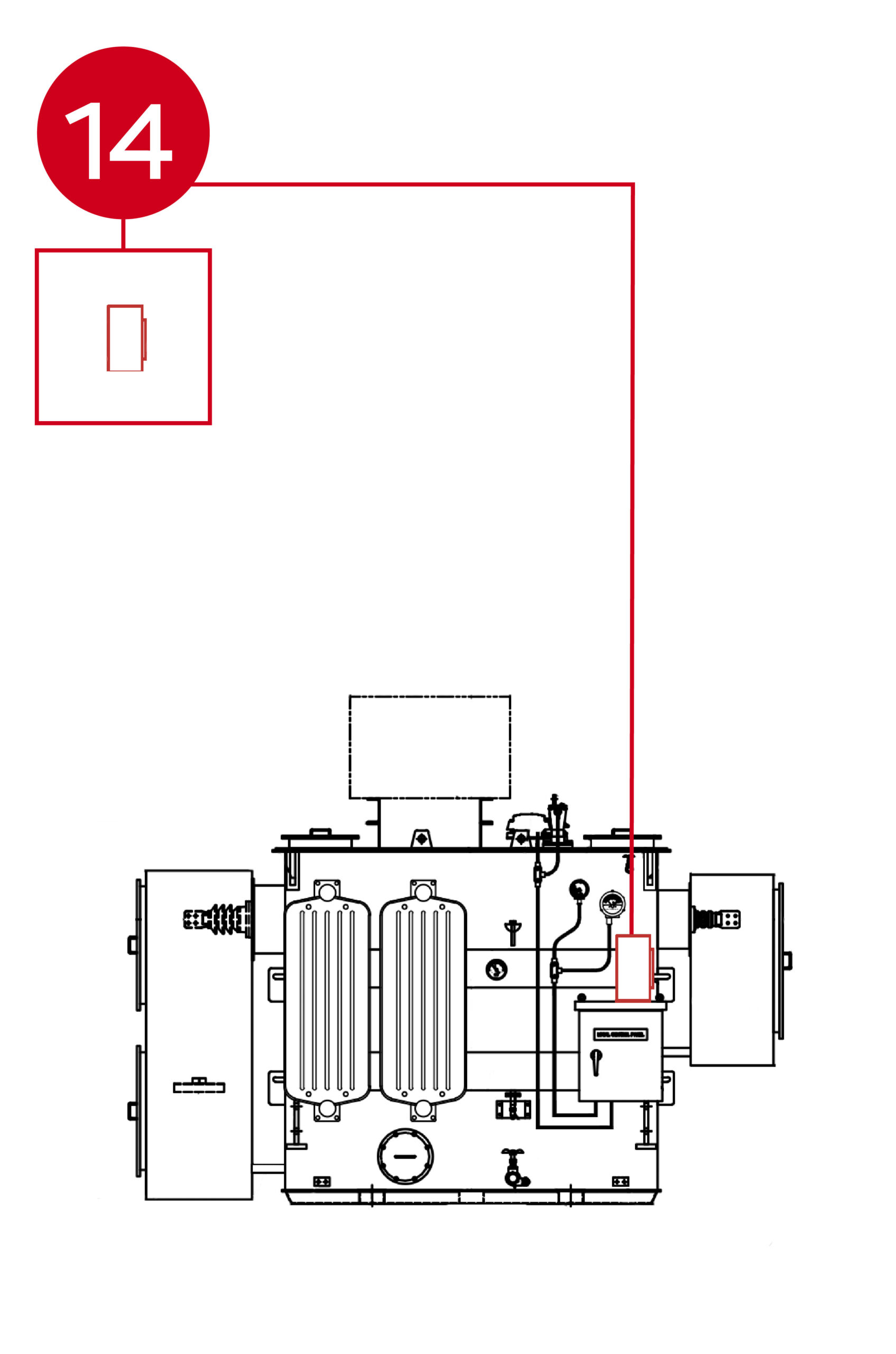

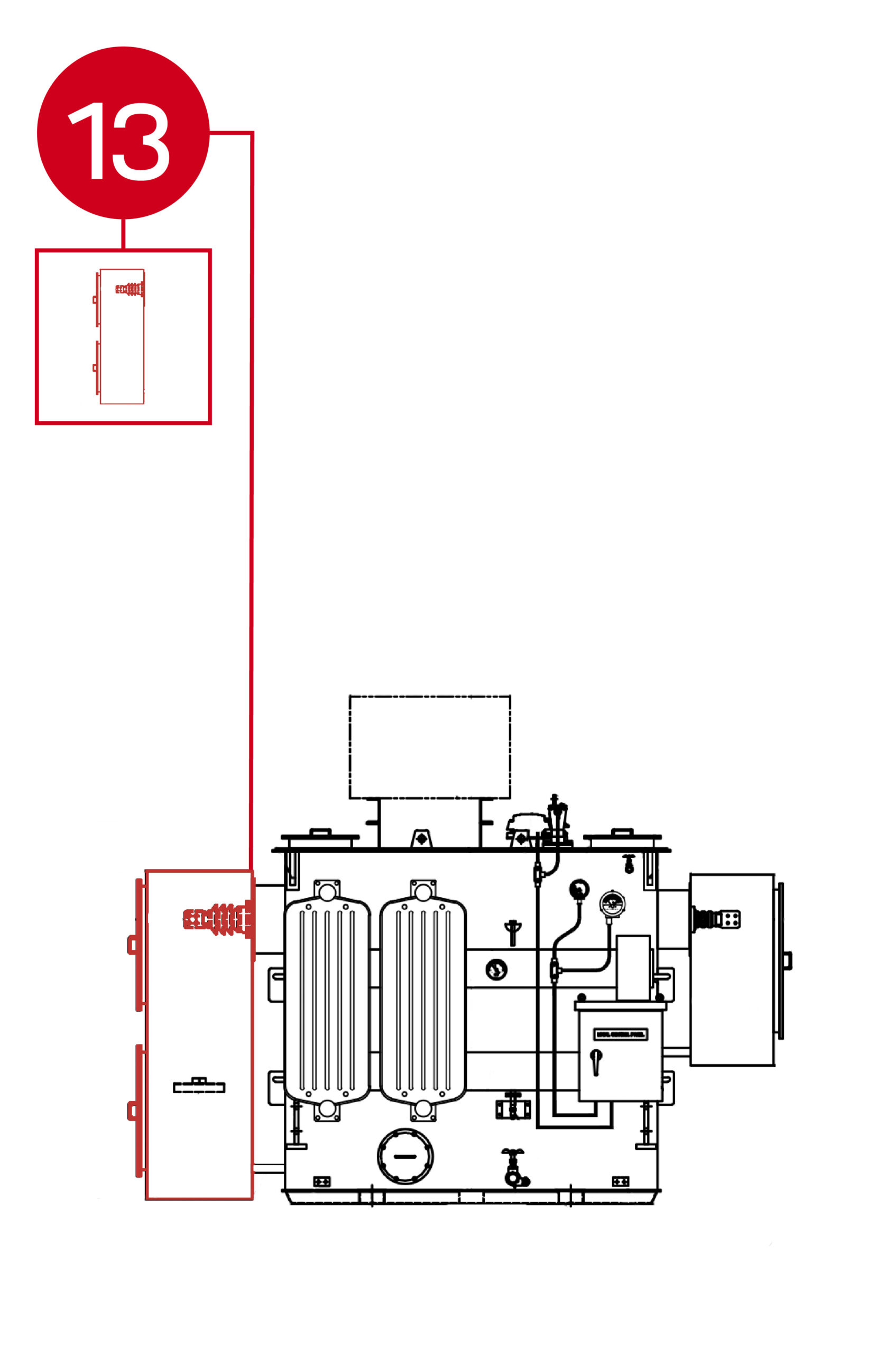

Low Voltage Air Terminal Chamber – A protective enclosure designed to completely surround the low voltage bushings for safety and environmental concerns.

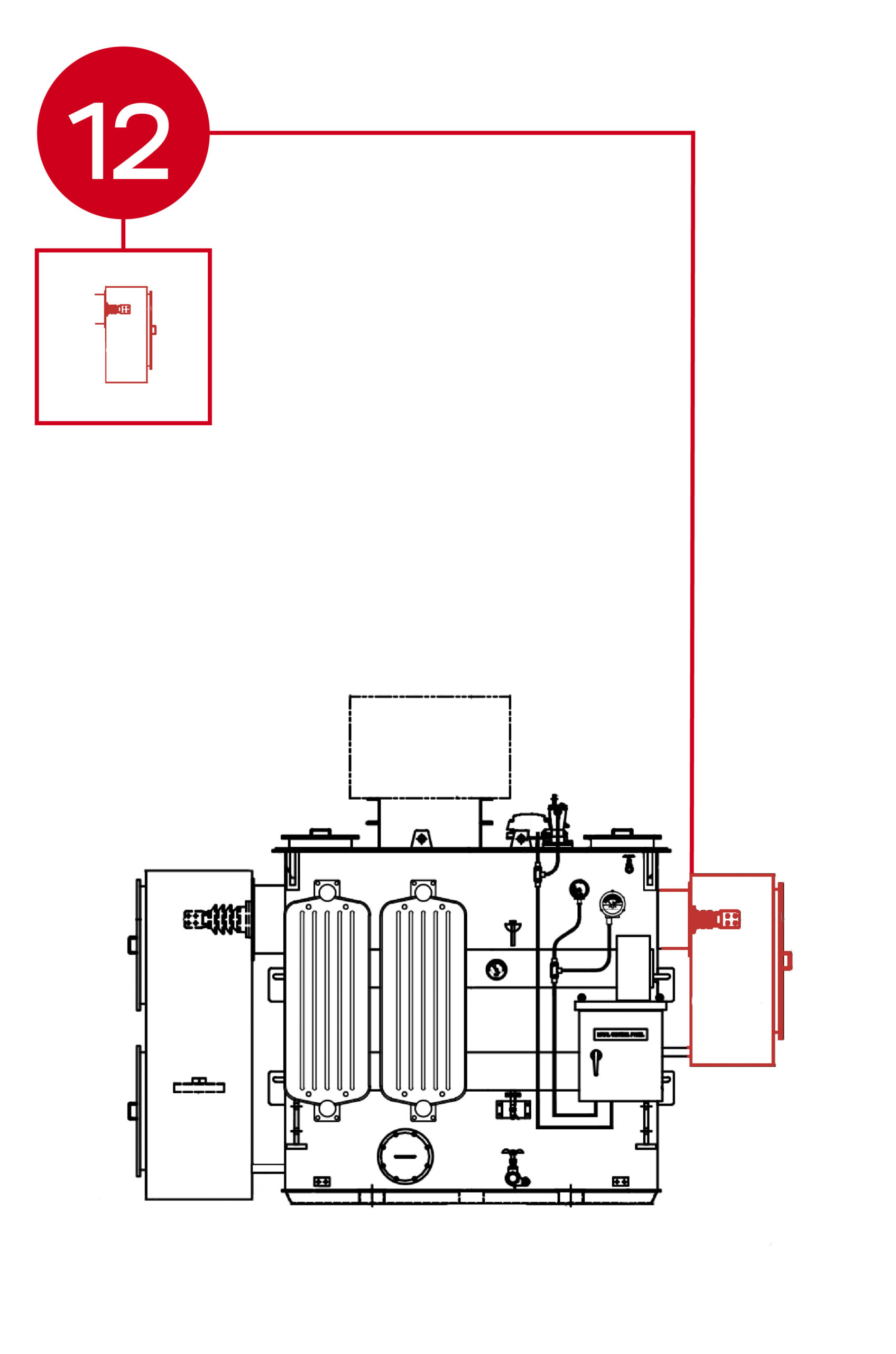

High Voltage Air Terminal Chamber – A protective enclosure designed to completely surround the high voltage bushings for safety and environmental concerns.

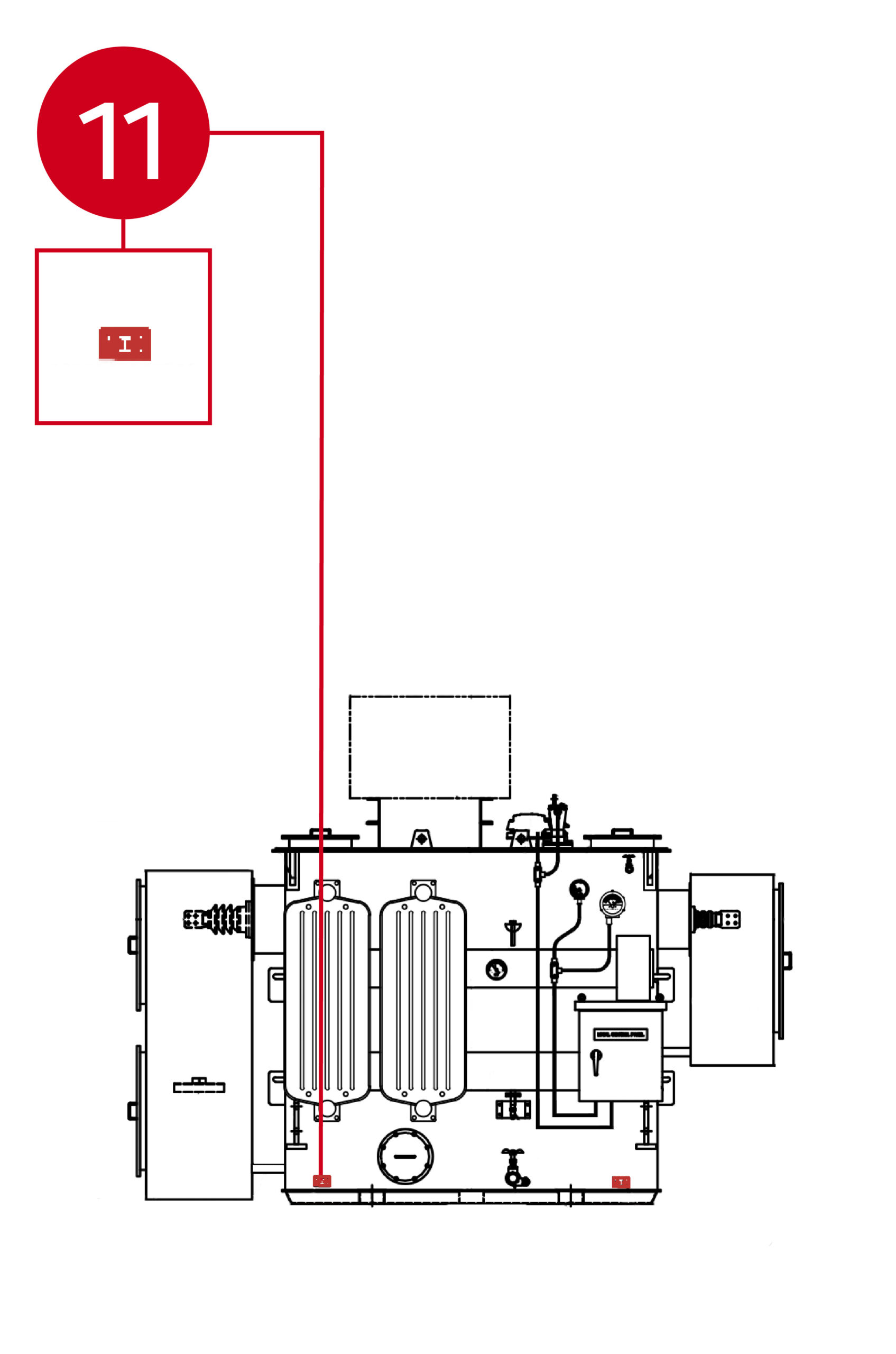

Nameplate – Also known as Data Plate, is installed on all transformers for identification.

High Voltage Bushings – Insulated connection point for incoming high-voltage supply cables.

Low Voltage Bushings - Low Voltage output points

Low Voltage Neutral Bushing – Provides a method for grounding the low voltage winding either by direct ground or through a resistor for ground fault control.

Tap Changer – Used to match incoming voltage and adjust outgoing Low Voltage

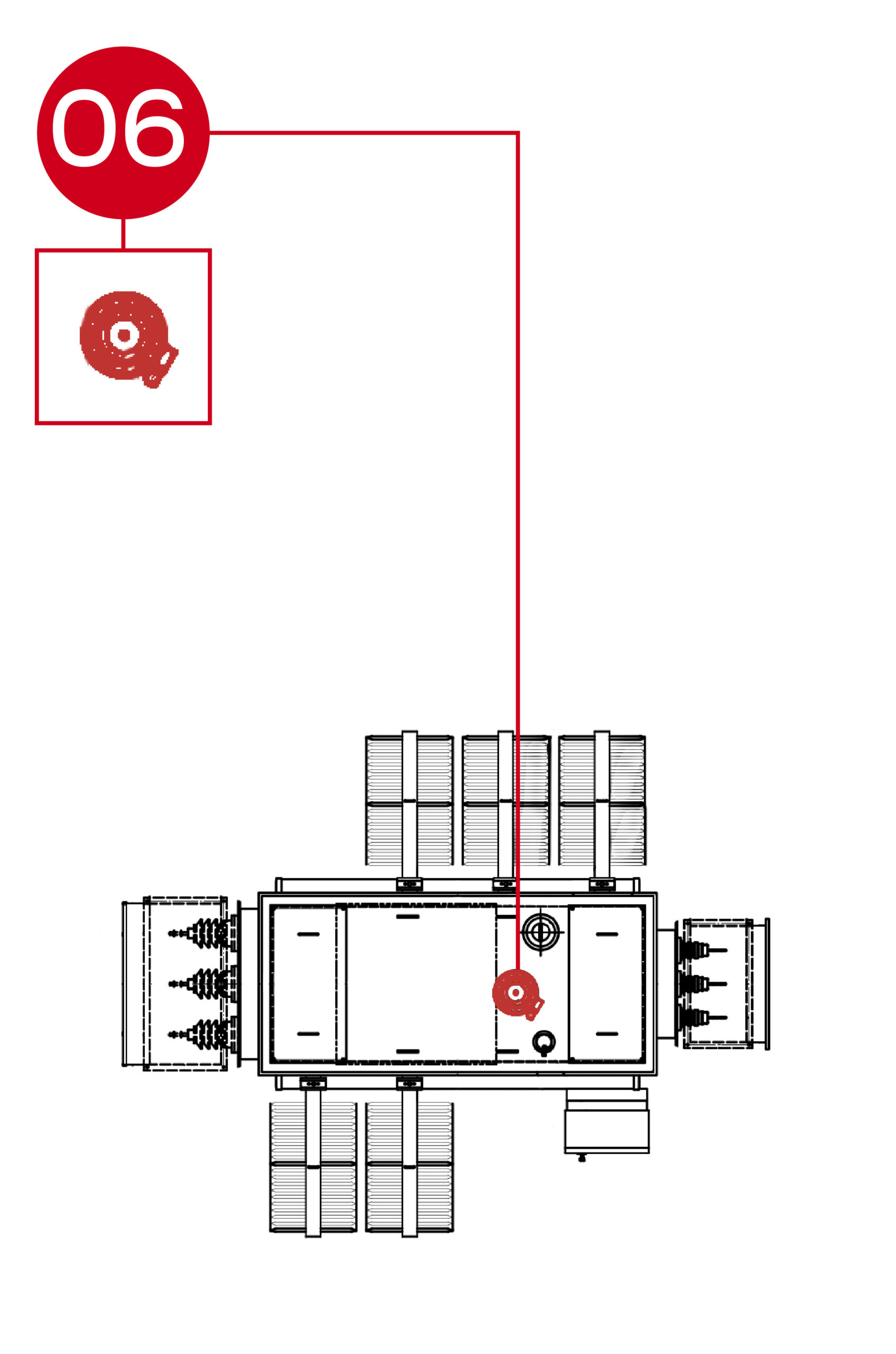

Standard Gauge Package - A combined monitoring assembly integrates vital indicators for transformer health and safety.

Pressure Relief Device – Used to automatically vent excess internal pressure caused by a transformer event or fault, to prevent catastrophic damage to the transformer tank.

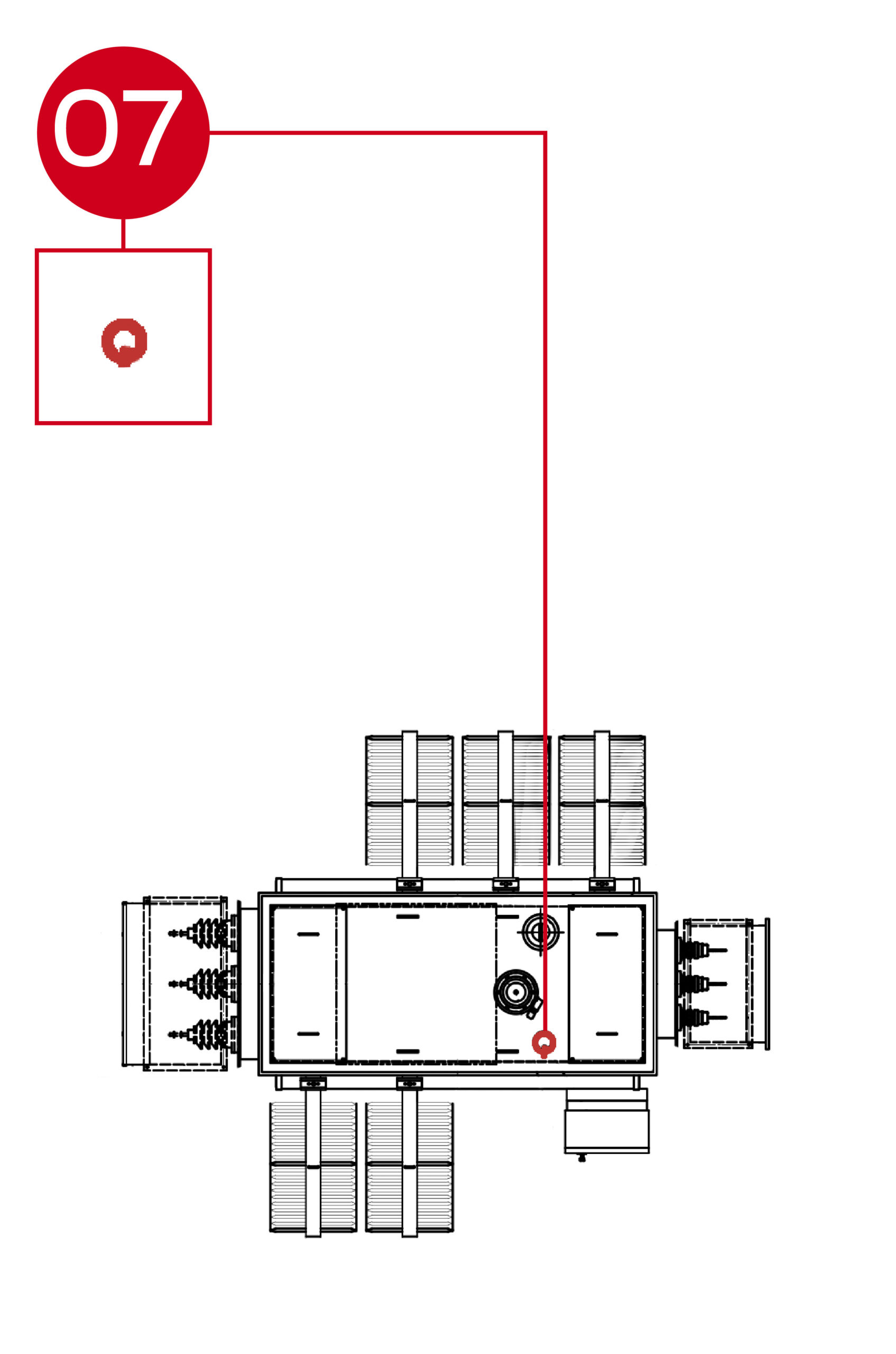

Rapid Pressure Rise Relay – The RPRR is designed to operate in conjunction with the Pressure Relief Device, except that it very quickly

Control Panel Cabinet - The local control panel houses controls, indicators, and relays for transformer operation and protection.

Radiators dissipate heat from the transformer’s insulating oil to maintain safe operating temperatures.

Location: Attached externally along the transformer sides.

Layout: Multiple finned panels or tubular sections bolted to the tank.

Function: Facilitates oil circulation and heat exchange, ensuring efficient cooling.

Drain Valve - Designed for safe oil management during maintenance or fluid sampling.

Grounding Provisions – Provides various acceptable safety grounding points

Low Voltage Air Terminal Chamber – A protective enclosure designed to completely surround the low voltage bushings for safety and environmental concerns.

High Voltage Air Terminal Chamber – A protective enclosure designed to completely surround the high voltage bushings for safety and environmental concerns.

Nameplate – Also known as Data Plate, is installed on all transformers for identification.

Getting started with ALAMO Transformer is simple and straightforward. Follow our easy, step-by-step guide to ensure a seamless experience from the first consultation to the final delivery.

Reach out to our team for an initial consultation via phone, email, our online form, or we can come to you!

Based on our assessment, we’ll present a customized solution that meets your exact needs, whether it’s an expedited repair, new transformer, rental unit, or reconditioned, remanufactured, or rewound transformer.

Once the proposal is approved, our team will move quickly to execute the plan, keeping you informed every step of the way.

We ensure timely delivery of your transformers and provide ongoing support to ensure everything operates smoothly.

Contact us today to speak with one of our experts, or explore our product categories to learn more about the solutions we offer.

Contact us today to speak with one of our experts, or explore our product categories to learn more about the solutions we offer.

Let us guide you to the right solution. Whether you need a transformer distributor, a quick quote, technical support, or a custom solution, Alamo Transformer is here to help. Trust us to be your go-to expert in transformer solutions.

Please complete the form below to get started finding the right product or services for your company.